Precision Electrical Component Manufacturer

Global Electric Component Manufacturing In Erie, Pa.

At Electrical Materials, we have specialized in high-quality electrical component manufacturing using copper alloys, built to deliver reliable performance since 1915. As one of the largest copper manufacturers in the United States, we supply utilities, distributors, transit authorities, OEMs, and military customers with precision machined components for demanding applications.

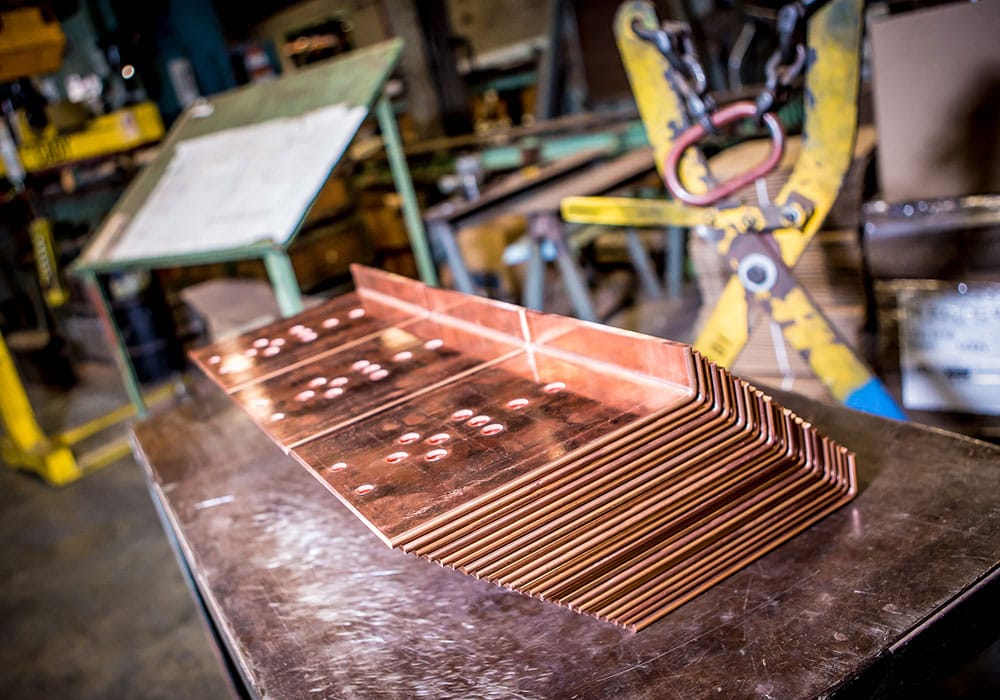

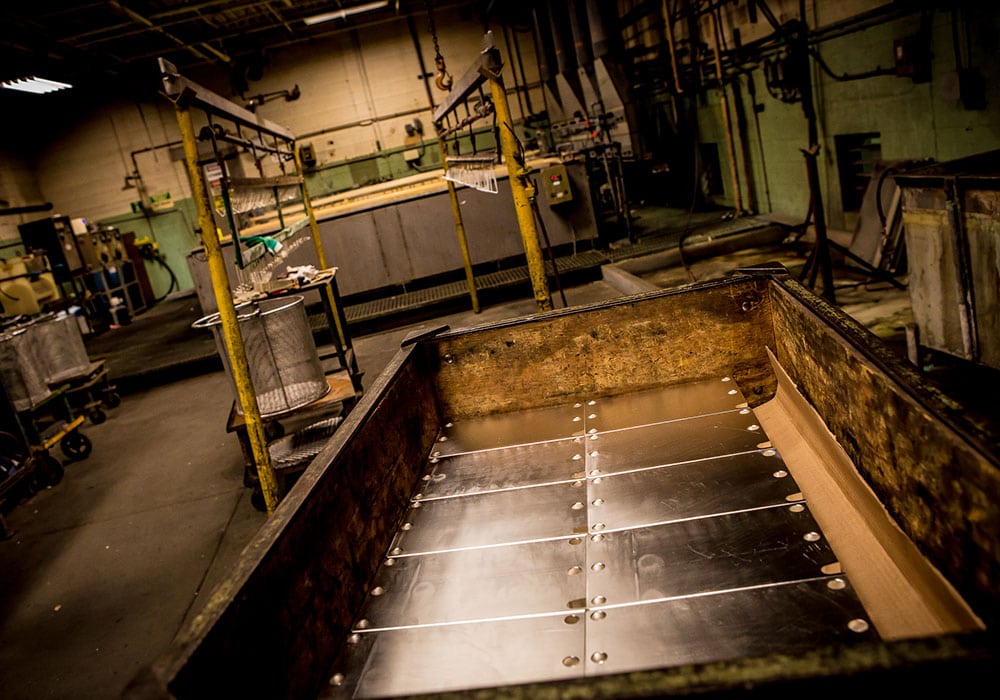

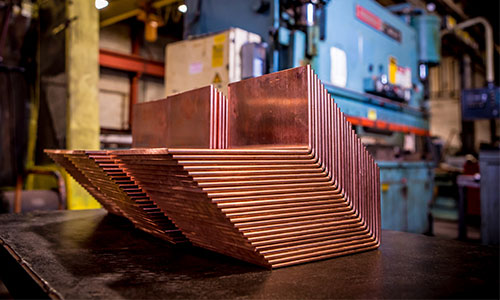

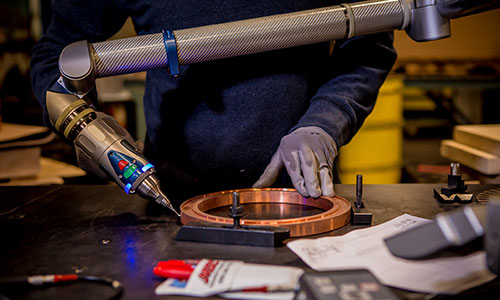

Electric Materials manufactures fabricated components that encompass a vast array of products for both electrical and mechanical applications that are cast, extruded, forged, brazed, machined, or electroplated. Our metalworking capabilities are all based on CNC technology providing you with the tightest tolerances and most efficient production methods.

Electrical Component Manufacturing Capabilities

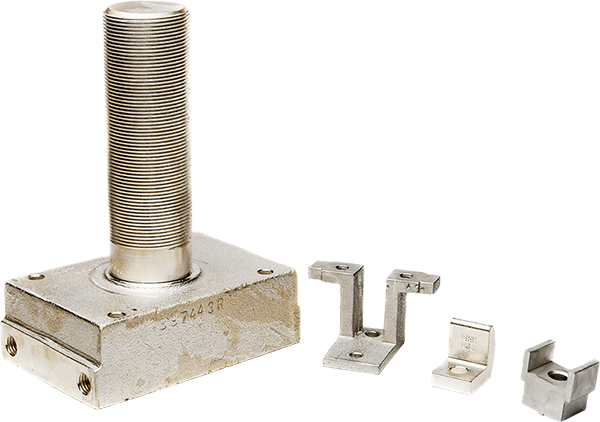

Electric Materials has the engineering abilities and vertical manufacturing integration to allow us to design and manufacture a complete line of copper and copper alloy components. Our engineering staff has the latest AutoCAD and Design Evaluation Software available to assess proposals. Engineering for both mechanical and electrical connectors centers around established designs and variations for custom applications.

Types of Electrical Components We Manufacture

The fabricated components we manufacture are for both electrical and mechanical applications that need to be cast, extruded, forged, brazed, machined, or electroplated. Many electrical components require more than one of these operations. A significant portion of the machined parts we produce function as electrical connectors. These can be manufactured to existing specifications, or we can review your drawings and provide you with a custom quote.

Our Manufacturing Equipment Capabilities

Electrical component manufacturing has been a central part of our business since the company’s inception in 1915. As one of the largest copper manufacturers in the United States, we supply utilities, distributors, transit authorities, OEMs, and military customers with precision machined components for demanding applications. Our metalworking capabilities are all based on CNC technology providing you with the tightest tolerances and most efficient production methods.

Our equipment includes:

- High capacity horizontal Mazak machining centers

- Three and six-axis CNC machining centers

- Auto feed and load cut off equipment

- Fully automated robotic work center

In-House Testing

With complete component production and testing capabilities, Electric Materials ensures that every product that leaves our factory is manufactured to the highest quality standards. Beginning with the initial design sessions all the way to final component testing and shipping, Electric Materials will stand behind the performance of your standard or custom-built product. We closely monitor the chemistry of each heat and billet to ensure that electrical and mechanical properties of the material meet or exceed required specifications. Material certifications are available for all products shipped, and Full Metal Tests are available if requested for an additional fee. We also offer engineering, design, and manufacturing services for electrical components produced by outside manufacturers.