Copper-Zinc Alloy C22600 for Cold-Formed Electrical Component Manufacturing

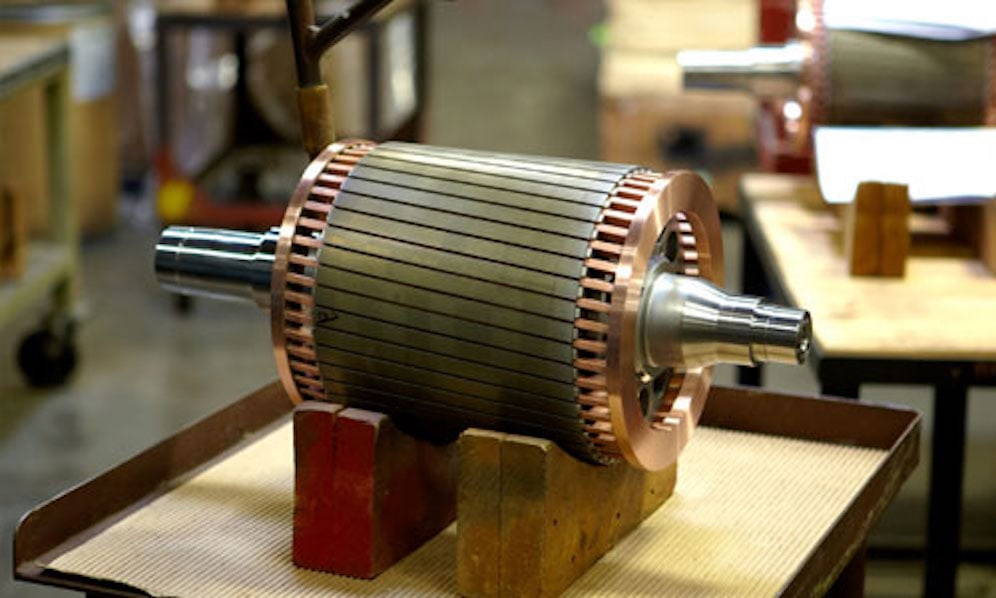

Copper-Zinc Alloy C22600 | Brass Extrusion Manufacturing for AC Rotors UNS C22600 Copper-Zinc Alloy has high corrosion resistance, free machining properties, and good welding capabilities. C22600 is a superb alloy for brass extrusion manufacturing. It is generally available in the form of rods for rotor bar applications. Among other copper-zinc alloys, the composition of C22600 copper-zinc is notably stronger than copper-zinc alloy C22000, making it a top choice in the plumbing, industrial, and electrical industries.. . .

Copper Alloy C23000 for Rotor Bar Manufacturing in Architectural Applications

Copper Alloy C23000 Copper Alloy C23000 has been specifically developed for rotor bar applications. Close control of the chemistry, including trace elements, at Electric Materials’ in-house casting facility, we control the electrical properties within a very narrow range. This ensures our customers the same electrical properties each time they order. C23000 has excellent cold workability as well as good hot workability for blanking, coining, drawing, piercing and punching, shearing, spinning, squeezing and swaging, stamping heading. . .

Copper Alloy C14700 Sulfurized Copper For Copper Casting Manufacturing

Copper Alloy C14700 | Copper Casting Manufacturing UNS C14700 sulfur bearing copper alloy has high corrosion resistance, free machining properties, and 90% minimum IACS conductivity. It is generally available in the form of wire and rod. C14700 copper is a lightly alloyed grade of copper, formulated for primary forming into wrought products. In addition, C14700 has a moderately high thermal conductivity and comparatively low tensile strength. Among wrought copper alloys, the composition of C14700 copper is. . .

Copper Zinc Alloy C21000 for Rotor Bar Manufacturing For Industrial Applications

Copper Zinc Alloy C21000– Electric Materials is Your AC Rotor Supplier Copper zinc alloy UNS C21000 is most commonly known for its resistance to corrosion. C21000 has superior corrosion resistance, good deep draw properties, is malleable, has moderate conductivity, all while possessing good strength. Typical uses for C21000 include ammunition components, coinage, medallions, and a wide variety of other applications. C21000 is a copper zinc alloy which is stronger and more durable than copper alloys.. . .

Commercial Bronze Alloy C22000–AC Rotor Manufacturing For Automotive Industries

Commercial Bronze Alloy C22000 for Rotor Bar Manufacturing Bronze alloy C22000 is great for all AC rotor and rotor bar manufacturing. Known for years as Commercial Bronze, this alloy derives its name from its rich bronze color. Its appealing color also makes it ideal for architectural applications such as hinges, doorknobs, and kick plates. C22000 has excellent cold workability as well as good hot workability for blanking, coining, drawing, piercing and punching, shearing, spinning, squeezing. . .