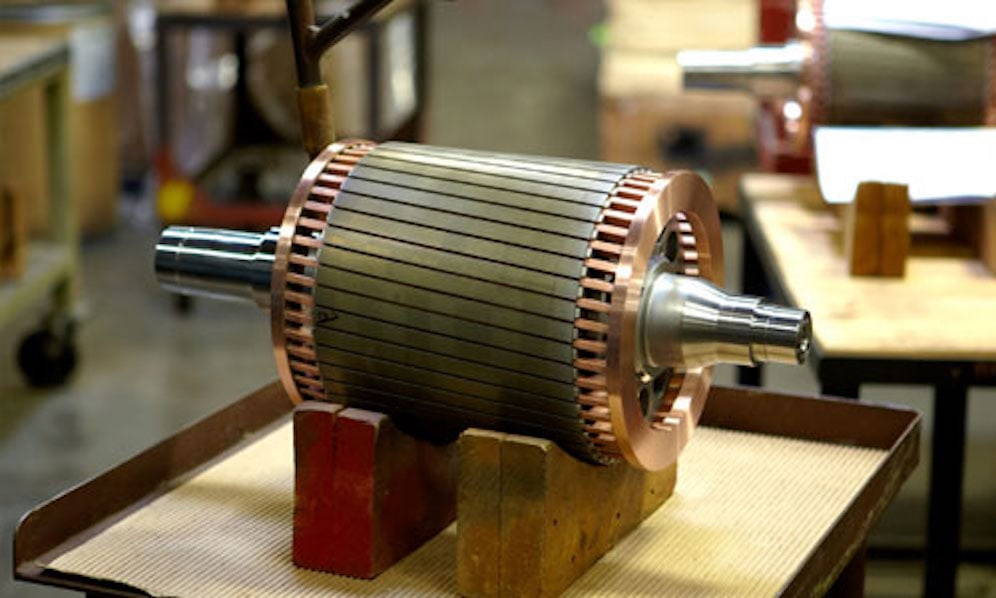

Copper Zinc Alloy C21000 for Rotor Bar Manufacturing For Industrial Applications

Copper Zinc Alloy C21000– Electric Materials is Your AC Rotor Supplier

Copper zinc alloy UNS C21000 is most commonly known for its resistance to corrosion. C21000 has superior corrosion resistance, good deep draw properties, is malleable, has moderate conductivity, all while possessing good strength. Typical uses for C21000 include ammunition components, coinage, medallions, and a wide variety of other applications. C21000 is a copper zinc alloy which is stronger and more durable than copper alloys. C21000 makes for a superior corrosion resistant, malleable, highly conductive metal for the industrial and electrical industries.

Material Specifications for Copper Alloy C21000—ASTM B134, B587, SAE J461 & more

Specifications

- ASTM B134- Standard Specification for Brass Wire

- ASTM B36- Standard Specification for Brass Plate, Sheet, Strip, And Rolled Bar

- ASTM B587- Standard Specification for Welded Brass Tube

- SAE J461- used for cast copper alloys to maintain the electrical and thermal conductivity properties, mechanical properties, yield strength, fatigue characteristics, formability, and machinability of these alloys

- SAE J463- Specifications for Wrought Copper and Copper Alloys

Choosing Copper Alloy C21000 for AC Rotor Manufacturing

Electric Materials’ C21000 Copper Alloy has been specifically developed for rotor bar applications. Close control of the chemistry, including trace elements, at our in-house casting facility, allows us to control the electrical properties within a very narrow range. This ensures our customers the same electrical properties each time they order. C21000 is often used in coin tokens and key blanks where corrosion is a key factor and conductivity are required.

For more information about Copper Alloy C21000, head over to Electric Materials’ Alloy Data Sheet to start learning more!